Specification

- उपयोग

- , , , , , , , , ,

- सहनशीलता

- मिलीमीटर (mm)

- फ़ीचर

- , , , , , , ,

- फ़ेस

- ग्रेड

- फॉर्मलडिहाइड उत्सर्जन मानक

- पीछे

- कोर मटेरियल

- मटेरियल

- प्लाइवुड टाइप

- मोटाई

- मिलीमीटर (mm)

- ग्लू

- नमी की मात्रा

- 5-15 %

- घनत्व

- किलोग्राम प्रति घन मीटर (kg/m3)

Trade Information

- Minimum Order Quantity

- 100 sheet टुकड़ाs

- भुगतान की शर्तें

- मुख्य घरेलू बाज़ार

About

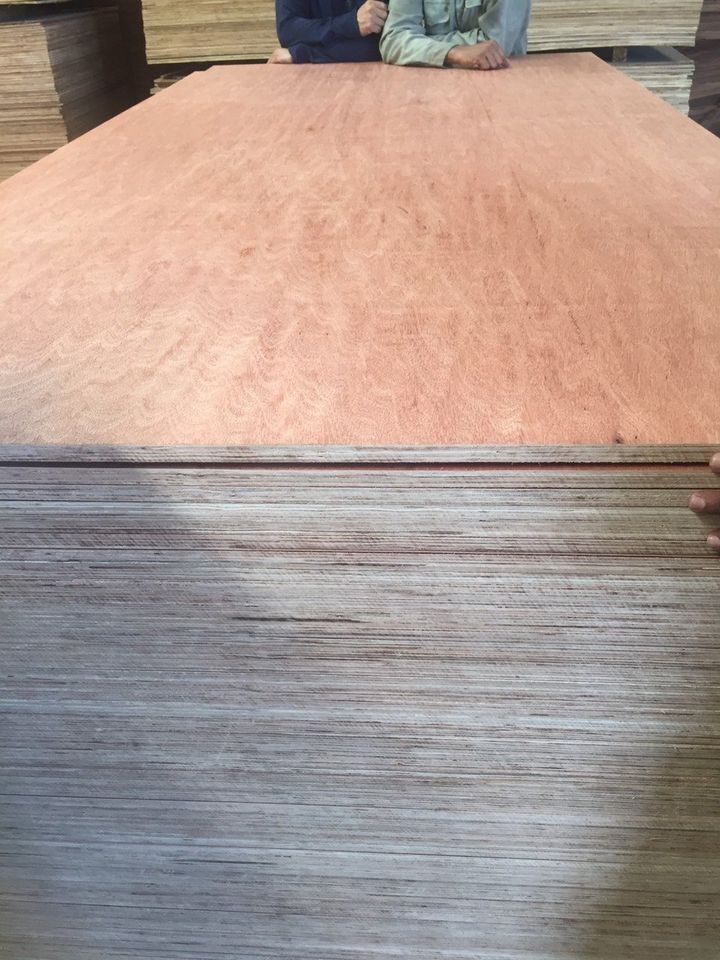

8mm commercial plywood is a lightweight and versatile plywood commonly used in interior applications such as furniture, paneling, partitions, and ceilings. This plywood is made from multiple thin layers (veneers) of wood that are glued together, with each layer oriented at right angles to the adjacent one. This cross-grain construction enhances its strength, durability, and resistance to warping or shrinking.

Key Features of 8mm Commercial Plywood:

- Thickness: The 8mm thickness makes it suitable for applications that require lightweight materials without compromising on strength.

- Grade: Commercial plywood typically comes in MR (Moisture Resistant) grade, meaning it is resistant to moisture but not fully waterproof. This makes it ideal for indoor use in areas that are not directly exposed to water.

- Surface Finish: The surface of commercial plywood is generally smooth, allowing for easy finishing with laminates, veneers, or paints.

- Cost-Effective: It is a budget-friendly option compared to other types of plywood, making it popular for economical projects.

- Workability: Due to its relatively thin structure, 8mm plywood is easy to cut, shape, and install, making it a favorite material among carpenters and builders.

Applications:

- Furniture: Often used for creating back panels, drawer bases, and light furniture.

- Partitions and Paneling: Ideal for interior partition walls and decorative wall paneling.

- Craft Projects: Its ease of use makes it suitable for small DIY projects.

In conclusion, 8mm commercial plywood is a highly functional and cost-effective choice for a variety of indoor uses, offering a good balance between durability and affordability.

Versatile Applications for Every Industry

Engineered for both indoor and outdoor use, this plywood excels in a wide range of applicationsfrom furniture and home dcor to wall panels, doors, and even shipping containers. Its moisture and alkaline-resistant properties make it perfect for construction and long-term storage needs. Whether youre outfitting a modern home or a commercial workspace, it reliably delivers performance and longevity.

Exceptional Durability & Environmental Standards

Manufactured from premium hardwood and a poplar core, the 8mm plywood withstands heavy wear and minimizes damage from acids or weather exposure. The use of E0-grade glue ensures minimal formaldehyde release, supporting eco-friendly projects. Its robust build provides a strong screw holding capacity, essential for construction and furniture manufacturing, without compromising on sustainability.

FAQs of Commercial Plywood 8mm:

Q: How is the 8mm Commercial Plywood suitable for both indoor and outdoor applications?

A: The plywood is manufactured with an OKOUME veneer, Poplar core, and phenolic glue, making it resistant to moisture, alkaline substances, and environmental wear. This ensures long-lasting durability for both indoor and outdoor uses, including furniture, doors, flooring, and external wall panels.Q: What makes this plywood environmentally friendly and safe for residential use?

A: This product meets E0 formaldehyde emission standards, ensuring very low levels of formaldehyde release. This, combined with the use of high-quality hardwood and phenolic glue, guarantees environmentally friendly construction practices suitable for homes, schools, and healthcare facilities.Q: When should I choose this plywood for construction or furniture projects?

A: You should select this plywood when you require strong screw holding, resistance to wear, acid, and moisture, as well as precise thickness tolerance. Its ideal for high-traffic areas, demanding construction projects, and places where environmental considerations are a priority.Q: Where can this plywood be effectively used within commercial or residential properties?

A: It is highly effective in furniture, wall panels, flooring, doors, and even for demanding applications like shipping containers and decorative elements. Its durability and resistance features make it suitable in both residential interiors and commercial settings.Q: What is the manufacturing process that ensures moisture and chemical resistance?

A: The plywood is bonded using phenolic glue and layered with OKOUME veneers, both of which contribute to its moisture, alkaline, and acid resistance. It undergoes quality checks to maintain the specified high density and precise thickness tolerance, making it robust and reliable.Q: How does the low formaldehyde releasing feature benefit indoor air quality?

A: By conforming to E0 standards, the plywood emits minimal formaldehyde, reducing indoor air pollution and contributing to a healthier environment for occupants, which is especially important for spaces like bedrooms, schools, and offices.Q: What are the key benefits of choosing this plywood for packaging and shipping containers?

A: Its high density, moisture and wear resistance, and strong structural integrity ensure that products are well-protected during transport and storage. The anti-cracking and anti-acid features further enhance longevity and safety in logistic environments.

Price: Â

- 50

- 100

- 200

- 250

- 500

- 1000+

अधिक Products in वाणिज्यिक प्लाईवुड Category

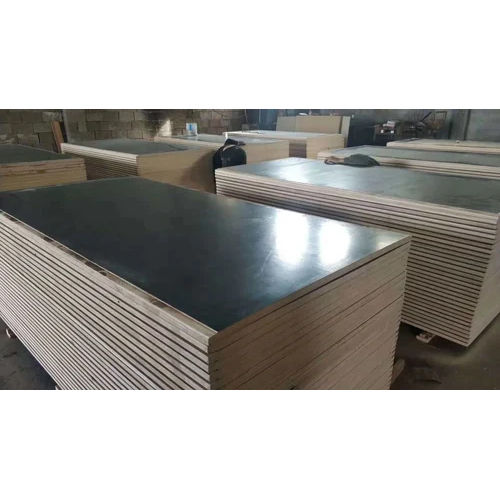

34 किलो हाई डेंसिटी ग्रेड फिल्म फेस 12 मिमी शटरिंग प्लाईवुड

साइज : 8x4 वर्ग फुट

मूल्य की इकाई : स्क्वायर फुट/स्क्वायर फुट्स

माप की इकाई : स्क्वायर फुट/स्क्वायर फुट्स

न्यूनतम आदेश मात्रा : 3200

मूल्य या मूल्य सीमा : आईएनआर

कोर मटेरियल : पोप्लर

वन साइड ब्लैक फिल्म फेस्ड एचडी ग्रेड कंटेनर फ्लोरिंग प्लाइवुड

साइज : 8x4 वर्ग फुट

मूल्य की इकाई : स्क्वायर फुट/स्क्वायर फुट्स

माप की इकाई : स्क्वायर फुट/स्क्वायर फुट्स

न्यूनतम आदेश मात्रा : 3200

मूल्य या मूल्य सीमा : आईएनआर

कोर मटेरियल : पोप्लर